Number of visits:62 seconds Update time:2024-05-29

Application:

Electric power,

Cold storage and other industrial sectors insulation,

Waterproofing project,

Liquid and gas transportation pipe network,

Chemical pipeline insulation engineering petroleum,

Chemical industry,

Central heating and heating network,

Central air conditioning ventilation pipe,

Municipal engineering, etc.

Application fields of PU for pipe insulation-Rigid pipe

District Heating / District Cooling

Rigid pipe

Fluid: Water

Outer jacket: Polyethylene

Carrier Pipe: Steel

Temperature: 3°C - 161°C

Rigid foam based on PUR

Moulded density of foam: 60 - 80 kg/m³

High requirements for the whole pipe system

Application fields of PU for pipe insulation-Pipe joints

District heating / District Cooling

Pipe joints

Fluid: Water

Outer jacket: Polyethylene

Carrier Pipe: Steel

Temperature: 3 °C - 161 °C

Rigid foam based on PUR

PU moulded density: 70 - 90 kg/m³

Application fields of PU for pipe insulation-Offshore

Offshore

Rigid and flexible pipes

Fluid: Oil, gas

Outer jacket: Steel, polyethylene, concrete

Carrier Pipe: Steel

Temperature: 3 °C - 120 °C

Rigid foam based on PUR

Open or closed cells

Compact PUR (Solid-PU)

Moulded density: 70 - 1150 kg/m³

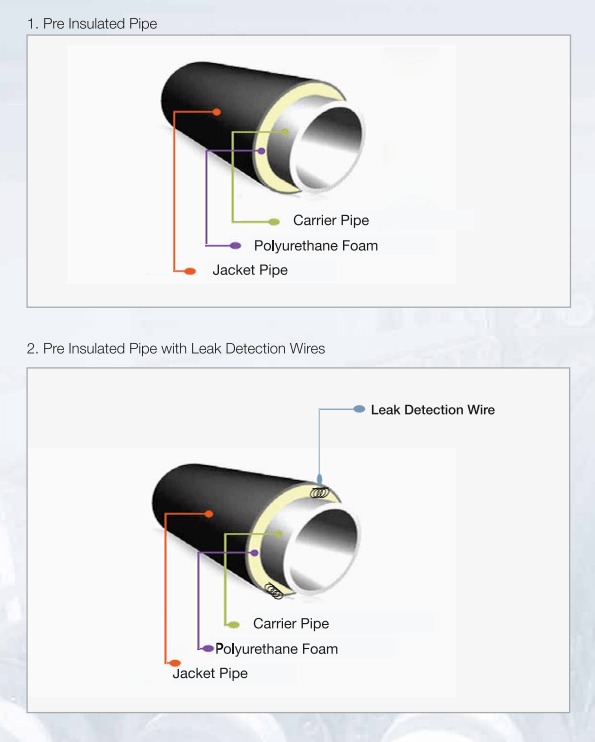

Pre-insulated pipes introduction

A pre-insulated pipe consists of three parts

The carrier pipe, made of made steel, stainless steel, plastic or copper.

The insulation, made of polyurethane foam (PUR foam) or polyisocyanurate foam (PIR foam), which is specially suited due to its high insulation qualities compared to mass and volume.

On the outside a protective casing of plastic or steel.

The choice of carrier pipe, foam type and foam thickness, as well as the material for the casing, is designed for a specific project together with the customer.

Casing:

As standard, industrial pipes are supplied with a PE-HD (polyethylene) casing, in black.

These casings have many advantages, as they are impact-proof, watertight, resistant to salt and chemicals, hygienic and non-corrosive. Pipes with black PE-HD casings are UV-resistant, as a result of the addition of UV-retardant

additives. Black casing pipes can therefore be used both outdoors

and indoors.

Pipes with black PE-HD casings are always used for buried pipe systems.

Standard steel pipes and casing pipes

Nominaldiameter | P235GHEN10217-2(ST.37.0) | P235GHEN10216-2(ST.35.8) | Stainlesslsometricdim.AISI 304/316 | Dairy pipes AISI304/316L | Series1 | Series2 | Series3 | Series4 | Series5 | |

Inches | DN | Welded(mm) | Seamless(mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

1/2" | 15 | 21.3x2.6 | 21.3x2.0 | 21.3x2.0 | 25.0x1.2 | 90 | 110 | 125 | 140 | 160 |

3/4" | 20 | 26.9x2.6 | 26.9x2.3 | 26.9x2.0 | 90 | 110 | 125 | 140 | 160 | |

1" | 25 | 33.7x2.6 | 33.7x2.6 | 33.7x2.0 | 90 | 110 | 125 | 140 | 160 | |

1 1/4" | 32 | 42.4x2.6 | 42.4x2.6 | 42.4x2.0 | 38.0x1.2 | 110 | 125 | 140 | 160 | 180 |

1 1/2" | 40 | 48.3x2.6 | 48.3x2.6 | 48.3x2.0 | 51.0x1.2 | 110 | 125 | 140 | 160 | 180 |

2" | 50 | 60.3x2.9 | 60.3x2.9 | 60.3x2.0 | 63.5x1.6 | 125 | 140 | 160 | 180 | 200 |

2 1/2" | 65 | 76.1x2.9 | 76.1x2.9 | 76.1x2.0 | 76.1x2.0 | 140 | 160 | 180 | 200 | 225 |

3" | 80 | 88.9x3.2 | 88.9x3.2 | 88.9x2.0 | 160 | 180 | 200 | 225 | 250 | |

100 | 108.0x3.6 | 108.0x3.6 | 101.6x2.0 | 180 | 200 | 225 | 250 | 280 | ||

4" | 100 | 114.3x3.6 | 114.3x3.6 | 114.3x2.0 | 200 | 225 | 250 | 280 | 315 | |

125 | 133.0x3.6 | 133.0x4.0 | 200 | 225 | 250 | 280 | 315 | |||

5" | 125 | 139.7x3.6 | 139.7x4.0 | 139.7x2.0 | 225 | 250 | 280 | 315 | 355 | |

150 | 159.0x4.0 | 159.0x4.5 | 250 | 280 | 315 | 355 | 400 | |||

6" | 150 | 168.3x4.0 | 168.3x4.5 | 168.3x2.0 | 250 | 280 | 315 | 355 | 400 | |

175 | 193.7x4.5 | 193.7x5.6 | 280 | 315 | 355 | 400 | 540 | |||

8" | 200 | 219.1x4.5 | 219.1x6.3 | 219.1x2.0 | 315 | 355 | 400 | 450 | 500 | |

10" | 250 | 273.0x5.0 | 273.0x6.3 | 273.0x2.6 | 400 | 450 | 500 | 560 | 630 | |

12" | 300 | 323.9x5.6 | 323.9x7.1 | 323.9x2.6 | 450 | 500 | 560 | 630 | 710 | |

14" | 350 | 355.6x5.6 | 355.6x8.0 | 500 | 560 | 630 | ||||

16" | 400 | 406.4x6.3 | 406.4x8.8 | 560 | 630 | 710 | ||||

18" | 450 | 457.0x6.3 | 457.0x10.0 | 630 | 710 | 800 | ||||

20" | 500 | 508.0x6.3 | 508.0x11.0 | 710 | 800 | 900 | ||||

22" | 550 | 559.0x6.3 | 559.0x12.5 | 710 | 800 | 900 | ||||

24" | 600 | 610.0x7.1 | 610.0x12.5 | 800 | 900 | 1000 | ||||

26" | 650 | 660.0x7.1 | 660.0x14.5 | 800 | 900 | 1000 | ||||

28" | 700 | 711.0x8.0 | 900 | 1000 | 1100 | |||||

30" | 750 | 762.0x8.8 | 900 | 1000 | 1100 | |||||

32" | 800 | 813.0x8.0 | 1000 | 1100 | 1200 | |||||

36" | 900 | 914.0x10.0 | 1200 | |||||||

40" | 1000 | 1016.0x11.0 | 1400 | |||||||

48" | 1200 | 1220.0x12.5 | ||||||||